Galvanized BS1139 Scaffolding Swivel Screw Nut Base Jack For Tower

Product Information

| Commodity | Scaffolding Swivel Screw Base Jack |

| Jack Length | 400-1000mm or Customized |

| Jack Diameter | 35/38mm or Customized |

| Main Material | Q235 or Q345 |

| Base Plate | 6x150x150mm |

| Surface treatment | Painted, galvanized, HDG, powder coated |

| Advantages | Competitive price, High-quality products, 24-hour after-sales service |

| Port | Nanjing/XINGANG |

| Currency | USD, RMB |

| Payment | L/C, T/T, 30% in advance |

| Package | Steel Pallet Or Customized |

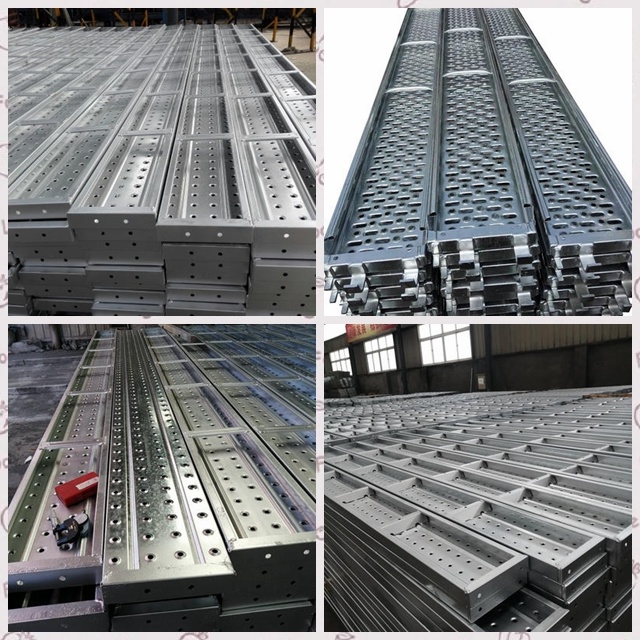

PRODUCT SHOW:

1.Scaffolding adjustable base jack nut,which is suitable for threaded tube or rod of 32mm,34mm,35mm,36mm,etc.

2.Material: casting or forged,both high quality

3.Surface finish: Electro galvanized, HDG, Black

7.Package:bags and steel pallet

8.No pinholes

9.Fast delivery and reasonable price

Product Images

OUR PRODUCT PACKAGE:

The below package are for your reference:

1. Little bag, good carton and strong pallet

2.Little inner box , then carton and strong wooden pallet

3. Gunny bag as your requests, then the strong pallet

4. Gunny bag, then wooden box.

5. We can custom the package according to your requests, and we can print your LOGO on your package.

How is base jack used in Scaffolding?

The base jack levels the scaffold tower when the tower legs are placed on surfaces of different elevations. It ensures all the legs will have (appx) equal bearing on the substrate(s) the tower rests upon.

Unless the jack is placed on something solid, it will need dunnage underneath it to properly transfer the leg load into the soil.

It is also used to 'fine tune' the height of the tower itself, so that height adjustments of up to around 12″ can be achieved.

Essentially, a base jack is a load bearing base and is used to hold standards/uprights (the vertical tubes) in place and help transfer the weight of the structure to the ground. The base jack is used to help spread the load and has a shank in the center to hold the tube in place. To eliminate sway, a facade brace is fitted to the face of the scaffold every 30 meters. The spacing of the upright scaffolding and base jacks is usually around every 2.1m but this can be reduced to 2m or 1.8m depending on the weight of the structure.

Other Scaffolding Materials we common export

Welcome to EK!